Introduction:

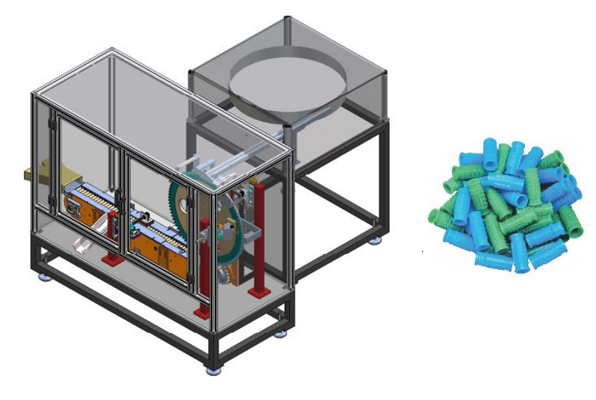

Discover Excellence in Drip Irrigation Quality Control with RDIM-300 Welcome to a new era of precision and reliability in drip irrigation quality control the RDIM-300 Round Dripper Inspection Machine. Drip irrigation plays a pivotal role in modern agriculture by optimizing water usage and enhancing crop yields. At Sigma Vision and Robotics, we understand that the heart of any irrigation system lies in the quality of its round drippers. That's why we've engineered the RDIM-300, a cutting-edge solution designed to guarantee the highest standards in round dripper quality.

Key Features:

High-Speed Precision: The RDIM-300 is engineered for efficiency, capable of inspecting up to 300 round drippers per minute. Its rapid inspection rate ensures your production line remains uninterrupted and highly productive.

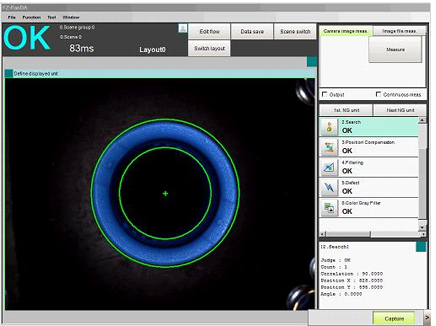

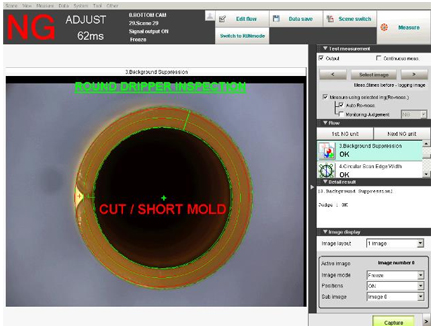

Advanced Vision Technology: Our state-of-the-art vision system, equipped with advanced cameras and image processing algorithms, detects even the most minute defects in round drippers. From imperfections in shape and color to dimensional variations, the RDIM-300 leaves no room for errors.

Intuitive User Interface: Operating the RDIM-300 is a breeze, thanks to its intuitive user interface. Easily configure inspection parameters and monitor the inspection process in real-time, putting you in control.

Tailored Inspections: Customize inspections to match your specific requirements. The RDIM-300 can be programmed to identify a wide range of defects, including shape irregularities, color inconsistencies, and size variations.

Efficient Reject System: Faulty round drippers are automatically sorted and rejected from the production line, ensuring that only flawless components make their way to your customers.

Built to Last: The RDIM-300 is built with longevity in mind, boasting a robust and durable design that guarantees reliable performance over the long haul

Seamless Integration: Seamlessly integrate the RDIM-300 into your existing production line. Its compact design and versatile compatibility make it a convenient addition to your workflow.

Benefits:

Enhanced Product Quality: With the RDIM-300, you can be confident that every round dripper meets the highest quality standards, reducing the risk of system malfunctions and water wastage.

Boosted Productivity: The machine's high-speed inspection capability ensures your production process remains efficient, saving you time and resources.

Cost Efficiency: By eliminating defective round drippers early in the production process, you reduce material waste and minimize costly product recalls.

Customer Satisfaction: Delivering reliable and defect-free round drippers to your customers enhances your reputation and fosters trust in your brand.

Sustainable Agriculture: Precision drip irrigation, made possible with the RDIM-300, contributes to a more sustainable and environmentally friendly agriculture industry.

Applications:

The RDIM-300 caters to manufacturers and suppliers in the agriculture and irrigation industry. It ensures the quality of round drippers used in various applications, including:

Agricultural irrigation systems

Greenhouse cultivation

Landscape and garden irrigation

Commercial farming

Sustainable agriculture initiatives

Conclusion:

Invest in the RDIM-300 Round Dripper Inspection Machine and elevate your drip irrigation production to unparalleled levels of quality and efficiency. At Sigma Vision and Robotics, we are dedicated to delivering innovative solutions that empower your business and promote sustainable agriculture. Contact us today to learn more about how the RDIM-300 can revolutionize your operation.

Discover Excellence in Drip Irrigation Quality Control with RDIM-300 Welcome to a new era of precision and reliability in drip irrigation quality control the RDIM-300 Round Dripper Inspection Machine. Drip irrigation plays a pivotal role in modern agriculture by optimizing water usage and enhancing crop yields. At Sigma Vision and Robotics, we understand that the heart of any irrigation system lies in the quality of its round drippers. That's why we've engineered the RDIM-300, a cutting-edge solution designed to guarantee the highest standards in round dripper quality.

Key Features:

High-Speed Precision: The RDIM-300 is engineered for efficiency, capable of inspecting up to 300 round drippers per minute. Its rapid inspection rate ensures your production line remains uninterrupted and highly productive.

Advanced Vision Technology: Our state-of-the-art vision system, equipped with advanced cameras and image processing algorithms, detects even the most minute defects in round drippers. From imperfections in shape and color to dimensional variations, the RDIM-300 leaves no room for errors.

Intuitive User Interface: Operating the RDIM-300 is a breeze, thanks to its intuitive user interface. Easily configure inspection parameters and monitor the inspection process in real-time, putting you in control.

Tailored Inspections: Customize inspections to match your specific requirements. The RDIM-300 can be programmed to identify a wide range of defects, including shape irregularities, color inconsistencies, and size variations.

Efficient Reject System: Faulty round drippers are automatically sorted and rejected from the production line, ensuring that only flawless components make their way to your customers.

Built to Last: The RDIM-300 is built with longevity in mind, boasting a robust and durable design that guarantees reliable performance over the long haul

Seamless Integration: Seamlessly integrate the RDIM-300 into your existing production line. Its compact design and versatile compatibility make it a convenient addition to your workflow.

Benefits:

Enhanced Product Quality: With the RDIM-300, you can be confident that every round dripper meets the highest quality standards, reducing the risk of system malfunctions and water wastage.

Boosted Productivity: The machine's high-speed inspection capability ensures your production process remains efficient, saving you time and resources.

Cost Efficiency: By eliminating defective round drippers early in the production process, you reduce material waste and minimize costly product recalls.

Customer Satisfaction: Delivering reliable and defect-free round drippers to your customers enhances your reputation and fosters trust in your brand.

Sustainable Agriculture: Precision drip irrigation, made possible with the RDIM-300, contributes to a more sustainable and environmentally friendly agriculture industry.

Applications:

The RDIM-300 caters to manufacturers and suppliers in the agriculture and irrigation industry. It ensures the quality of round drippers used in various applications, including:

Agricultural irrigation systems

Greenhouse cultivation

Landscape and garden irrigation

Commercial farming

Sustainable agriculture initiatives

Conclusion:

Invest in the RDIM-300 Round Dripper Inspection Machine and elevate your drip irrigation production to unparalleled levels of quality and efficiency. At Sigma Vision and Robotics, we are dedicated to delivering innovative solutions that empower your business and promote sustainable agriculture. Contact us today to learn more about how the RDIM-300 can revolutionize your operation.

The System is designed to Identify following defects on Round drippers :

- Short Molding

- Flash Defect

- Filter-Holes Blocked

- Eccentric or Sample Deformation

- Foreign Colour

- Foreign Sample

- Damaged Sample

BELOW IMAGES SHOWS THE CAMERA RESULT FOR OK AND BAD SAMPLES :

OK SAMPLE

BAD SAMPLE (CUT/SHORT MOLD DEFECT)

BAD SAMPLE (FLASH)

BAD SAMPLE (FILTER HOLES BLOCKED)

Elevated Hopper Feeder :

- The products to be Inspected are manually loaded to the Hopper.

Rotary Bowl Feeder, Chute & Guiding Mechanism :

- From here, product is gradually carried through the Chute, in a linear fashion to the Guiding vertical star wheel which ultimately feeds the product to the linear conveyor.

Camera based Inspection System :

- The Camera based Inspection Station consists of Single High-Resolution Color Camera System with a Very Higher End Digital Processor for identifying the OK/NG samples as per your requirements.

High Speed Rejection System :

- This consists of High-Speed Pneumatic operated nozzle to sort out the defective dripper samples from the Production line.

Output Batch Diverter System :

- This consists of Pneumatic operated diverter assembly which diverts Good materials from One Collection bin to Another Collection bin.

- This machine is capable of inspecting up-to 280-300 Components per Minute, Depending upon the flow of the product.